Pipes

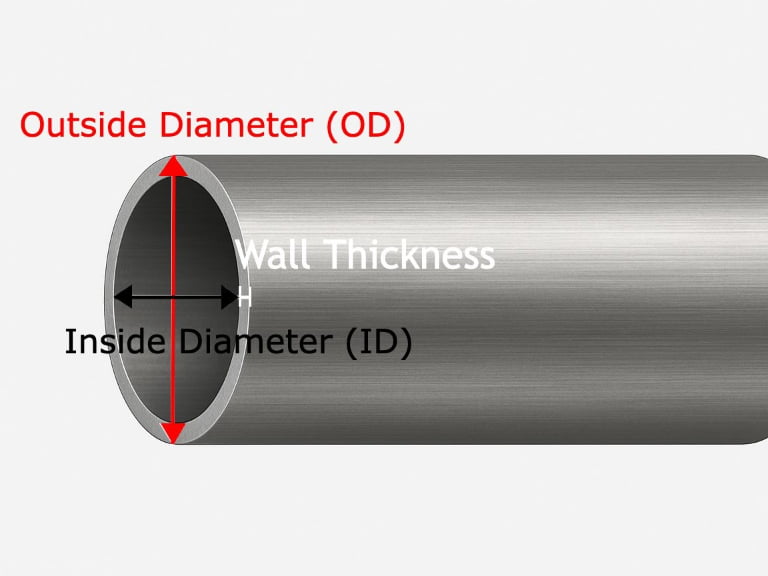

A steel pipe is steel with a hollow section and its length is much greater than its diameter or circumference. According to the cross-sectional shape, it is divided into round, square, rectangular, and special-shaped steel pipes; according to the material, it is divided into carbon structural steel pipes, low-alloy structural steel pipes, alloy steel pipes, […]

Read More